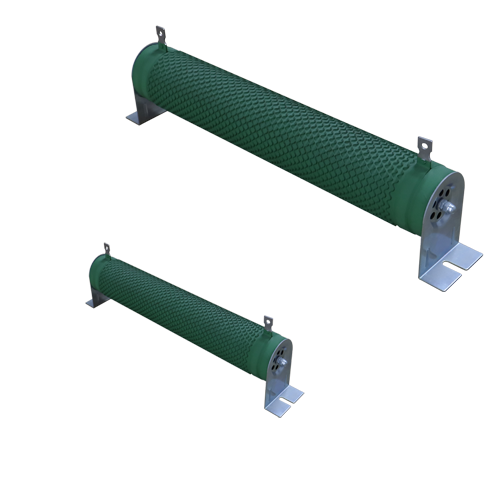

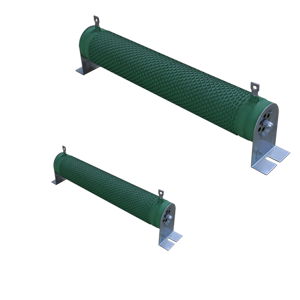

Silicone Coated Tubular Power Wirewound Resistors

Wirewound braking resistor(HPR)

- Rated Power: 50W-2500W

- Resistance Range: 1R-10KR

- TCR: ≤300ppm

- Standard tolerance: ±5%

- Product description: Wirewound braking resistor, Silicone Coated, Tubular, 50W-2500W, high power is customizable.

Wirewound braking resistor, Silicone Coated, Tubular, 50W-2500W

Wirewound braking resistor supports the use of numerous taps, has low impedance, and can be fabricated in various shapes to support a wide range of applications.

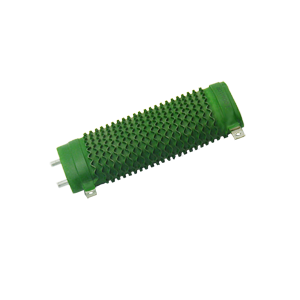

Construction:

- A tubular ceramic with two terminals.

- A ceramic tubular is wound with wave-shaped alloy ribbon.

- Terminal bands are spot welded after installation on the core.

- A resistance-alloy ribbon wire is crimped and edgewound onto the core.

- Non-flammable resin insulation is applied after cooling and drying through a temperature process.

- The resistance value range is relatively low due to alloy material limitations.

Features:

1. Rated power range: 50W-2,500W

2. Operating voltage range: <1.2kV

3. Rated resistance range: 1R-10KR

4. Resistance tolerance: ±5%, ±10%

5. Dielectric strength: AC3KV 50Hz/5s

6. Fixed, tapped styles, or adjustable type are available

7. Special terminals are available for unusual applications

Applications:

1. Load test

2. Equipment discharge

3. Automated control and inverter's energy loss brake.

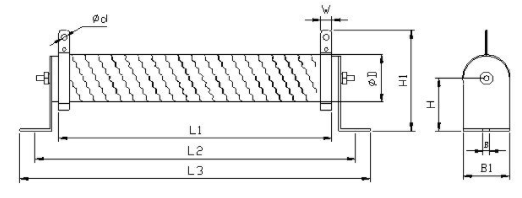

Dimensions:

|

Type |

Rated power (w) |

Resistance range (Ω) |

Tolerance |

Dimension (mm) |

Remark |

|||||||||

| L1±2 | L2±5 | L3±3 | D±2 | B | B1 | H | H1±3 | W | d | |||||

| RXG | 50 | 0.1~5K |

±5%(J) ±10%(K) |

102 | 126 | 146 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 |

Customization is welcome. |

| RXG | 60 | 0.1~8.2K | 102 | 126 | 146 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 | ||

| RXG | 80 | 0.1~10K | 152 | 174 | 196 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 | ||

| RXG | 100 | 0.1~10K | 182 | 204 | 226 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 | ||

| RXG | 150 | 0.1~10K | 195 | 217 | 239 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 200 | 0.1~10K | 195 | 217 | 239 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 300 | 0.1~10K | 282 | 304 | 326 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 400 | 0.1~10K | 282 | 304 | 326 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 500 | 0.1~10K | 318 | 340 | 362 | 50 | 8.0 | 50 | 45 | 101 | 16 | 6.0 | ||

| RXG | 600 | 0.1~10K | 318 | 340 | 362 | 50 | 8.0 | 50 | 45 | 101 | 16 | 6.0 | ||

| RXG | 750 | 0.1~10K | 318 | 340 | 362 | 50 | 8.0 | 50 | 45 | 101 | 16 | 6.0 | ||

| RXG | 1000 | 0.1~10K | 300 | 325 | 350 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 1200 | 0.1~10K | 415 | 440 | 465 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 1500 | 0.1~10K | 415 | 440 | 465 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 2000 | 0.1~10K | 510 | 535 | 560 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 2500 | 0.1~10K | 600 | 625 | 650 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

Categories

- Wirewound Power Resistors

- Shunt Resistors

- Blower Motor Resistors

- Current Sensing Resistors

- Dynamic braking resistor

- Composition Resistors

- Water Cooled Resistor

- Ceramic Encased Resistor

- Crowbar Resistor

- Load Bank

- Neutral Grounding Resistor

- Power Thick Film Resistor

- Rheostats

- Film Resistors

- High Voltage Resistors

- LED Autolamps Load Resistors

- Resistor Network

- Potentiometer

Latest News

Contact Us

Contact: Tom Tan

Phone: (86)-15602914508

Tel: (86)-755-28158718

Email: [email protected]

Add: 1st Floor, GUOYAO Industry Park, HUANGJIANG Town, DONGGUAN, GUANGDONG, China

Sales Team

Sales Team