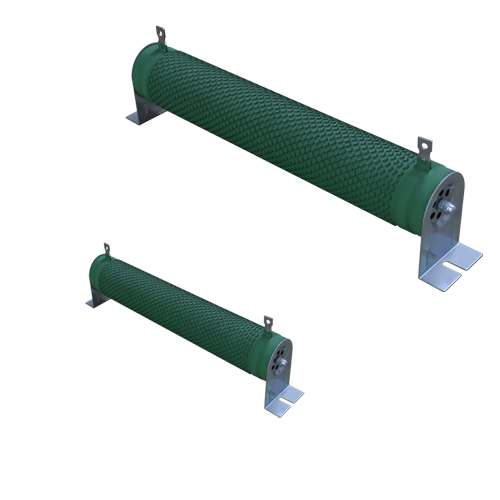

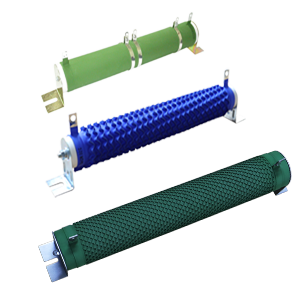

Silicone Coated Tubular Power Wirewound Resistors

Tubular Wirewound Resistor

- Rated Power: 50W-2500W

- Resistance Range: 1R-10KR

- TCR: ≤300ppm

- Standard tolerance: ±5%

- Product description: Fixed Tubular Wirewound Resistor, High Power, Silicone Coated, 50W-2500W, Quick Connector

RXG Fixed Tubular Wirewound Resistor, High Power, Silicone Coated, 50W-2500W

RoHS compliant and lead free, order individual replacement units, or entire grids with various mounting configurations, or custom specifications, contact us to discuss the details.

Features:

- Special terminals are available for unusual applications.

- Single and double quick connect terminals can be specified.

- Standard lug terminals available with or without terminal hardware.

- Special temperature coefficients, tolerances, and resistance value can be specified.

- Standard resistance tolerance is ±5% and ±10%. Closer tolerances are available upon request.

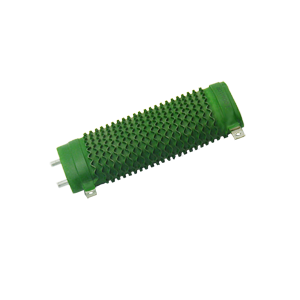

- The wire is spot welded to the terminal bands and then "fastened" onto the core with a silicone, cement, or vitreous enamel coating.

Constructions:

- Coated with non-flammable resin in high temperature.

- Insulation is applied through a high-temperature process and the mounts are attached.

- A tubular ceramic has two terminals and is wound with copper roundwire or chromium alloy roundwire to provide the resistance.

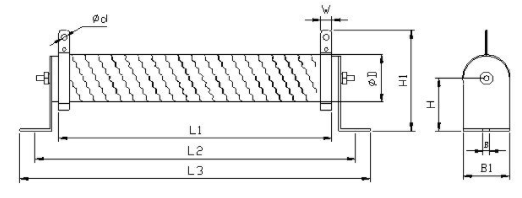

Dimensions:

|

Type |

Rated power (w) |

Resistance range (Ω) |

Tolerance |

Dimension (mm) |

Remark |

|||||||||

| L1±2 | L2±5 | L3±3 | D±2 | B | B1 | H | H1±3 | W | d | |||||

| RXG | 50 | 0.1~5K |

±5%(J) ±10%(K) |

102 | 126 | 146 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 |

Customization is welcome. |

| RXG | 60 | 0.1~8.2K | 102 | 126 | 146 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 | ||

| RXG | 80 | 0.1~10K | 152 | 174 | 196 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 | ||

| RXG | 100 | 0.1~10K | 182 | 204 | 226 | 28 | 6.5 | 28 | 28 | 62 | 10 | 4.5 | ||

| RXG | 150 | 0.1~10K | 195 | 217 | 239 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 200 | 0.1~10K | 195 | 217 | 239 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 300 | 0.1~10K | 282 | 304 | 326 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 400 | 0.1~10K | 282 | 304 | 326 | 40 | 8.0 | 40 | 41 | 86 | 12 | 5.5 | ||

| RXG | 500 | 0.1~10K | 318 | 340 | 362 | 50 | 8.0 | 50 | 45 | 101 | 16 | 6.0 | ||

| RXG | 600 | 0.1~10K | 318 | 340 | 362 | 50 | 8.0 | 50 | 45 | 101 | 16 | 6.0 | ||

| RXG | 750 | 0.1~10K | 318 | 340 | 362 | 50 | 8.0 | 50 | 45 | 101 | 16 | 6.0 | ||

| RXG | 1000 | 0.1~10K | 300 | 325 | 350 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 1200 | 0.1~10K | 415 | 440 | 465 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 1500 | 0.1~10K | 415 | 440 | 465 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 2000 | 0.1~10K | 510 | 535 | 560 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

| RXG | 2500 | 0.1~10K | 600 | 625 | 650 | 60 | 8.5 | 60 | 59 | 119 | 16 | 6.0 | ||

Categories

- Wirewound Power Resistors

- Shunt Resistors

- Blower Motor Resistors

- Current Sensing Resistors

- Dynamic braking resistor

- Composition Resistors

- Water Cooled Resistor

- Ceramic Encased Resistor

- Crowbar Resistor

- Load Bank

- Neutral Grounding Resistor

- Power Thick Film Resistor

- Rheostats

- Film Resistors

- High Voltage Resistors

- LED Autolamps Load Resistors

- Resistor Network

- Potentiometer

Latest News

Contact Us

Contact: Tom Tan

Phone: (86)-15602914508

Tel: (86)-755-28158718

Email: [email protected]

Add: 1st Floor, GUOYAO Industry Park, HUANGJIANG Town, DONGGUAN, GUANGDONG, China

Sales Team

Sales Team